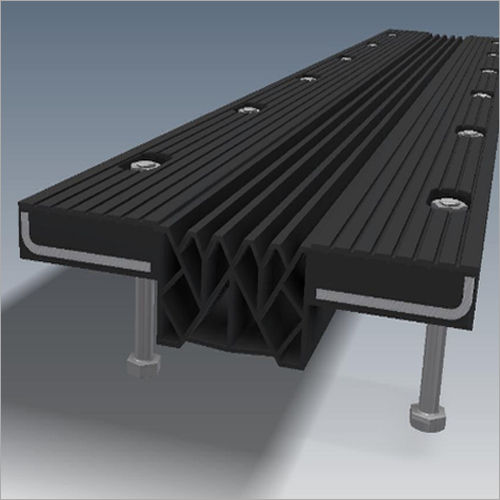

Omega Seal Expansion Joint

Price 5000 INR/ Piece

Omega Seal Expansion Joint Specification

- Media

- Water, Oil, Gas

- Max. Temperature

- 150C

- Surface Treatment

- Galvanized

- Flange

- ANSI / DIN standard

- Usage

- Industrial

- Material

- Other

- Technique

- Hot Rolled

- Type

- Omega Seal Expansion Joint

- Connecting Type

- Flanged

- Shape

- Omega

- Product Type

- Expansion Joint

- Head Code

- Round

- Working Pressure

- Up to 10 bar

- Installation

- Easy Flanged/Butt Weld Connection

- Standard Length

- Customizable

- Sealing Element Material

- Synthetic Rubber/Elastomer

- Corrosion Resistance

- High

- Color

- Silver/Grey

- Expansion Movement

- Axial, Lateral, Angular

- Application

- Piping and Pipeline Systems

Omega Seal Expansion Joint Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Main Export Market(s)

- Asia, Australia, Central America, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About Omega Seal Expansion Joint

Specification

|

Colour |

Grey |

|

Material |

Steel |

|

Shape |

Omega |

|

Surface Treatment |

Galvanized |

|

Country of Origin |

Made in India |

|

Brand |

Trident |

|

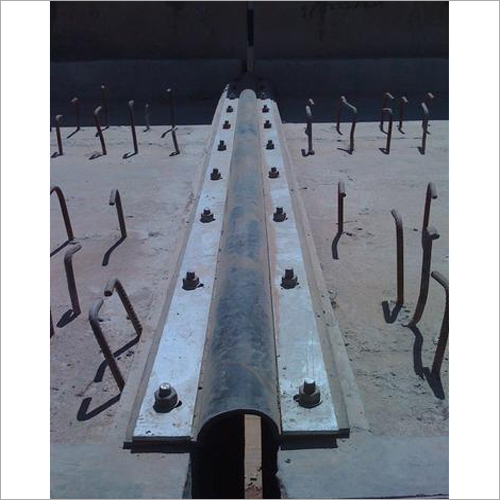

Usage/Application |

Bridge Constructions |

Advanced Corrosion Resistance

Omega Seal Expansion Joints feature a galvanized surface treatment and high-quality synthetic rubber/elastomer sealing, offering robust protection against corrosion in harsh industrial settings. This ensures long-term durability and minimized maintenance demands, making them a reliable solution for pipelines exposed to aggressive substances.

Flexible Expansion Movement

Engineered to support axial, lateral, and angular expansions, these joints excel in accommodating pipe movement due to temperature fluctuations, pressure changes, and seismic activities. Their adaptability helps maintain pipeline integrity, reducing stress and preventing leaks or structural damage.

Customizable and Effortless Installation

Available in standard and custom lengths, Omega Seal Expansion Joints are designed for simple integration into piping systems using flanged or butt weld connections. Their easy installation makes them suitable for both new projects and retrofits across diverse industrial applications.

FAQs of Omega Seal Expansion Joint:

Q: How is the Omega Seal Expansion Joint installed in piping systems?

A: The Omega Seal Expansion Joint can be installed using flanged or butt weld connections, providing flexibility and ease in setup. This allows for quick integration into new or existing pipeline systems with minimal technical complexity.Q: What types of movement does this expansion joint accommodate?

A: This expansion joint is designed to support axial, lateral, and angular movements, making it suitable for pipelines that undergo expansion, contraction, and vibration due to operational or environmental factors.Q: When should I use an Omega Seal Expansion Joint with high corrosion resistance?

A: You should use an Omega Seal Expansion Joint when your piping system is exposed to harsh chemicals, moisture, or variable temperatures that may lead to corrosion. Its galvanized surface and synthetic elastomer sealing material ensure longevity in such environments.Q: Where are Omega Seal Expansion Joints typically applied?

A: Omega Seal Expansion Joints are used in industrial piping and pipeline systems, covering sectors such as chemical processing, water treatment, oil and gas, and utilities where movement and corrosion resistance are critical.Q: What is the process for customizing the length of this expansion joint?

A: To customize the length, you can specify project requirements during the ordering stage. The manufacturer will tailor the joint to your dimensions, ensuring a precise fit for your application.Q: How does the synthetic rubber/elastomer sealing benefit pipeline systems?

A: The synthetic rubber/elastomer sealing provides excellent flexibility, watertight sealing, and resistance to various chemicals, helping prevent leaks and maintaining the integrity of piping systems under diverse operating conditions.Q: What are the usage advantages of Omega Seal Expansion Joints for industrial pipelines?

A: These joints offer high corrosion protection, adapt to complex movement patterns, and are easy to install. Their customizable design ensures compatibility with different pipeline configurations, reducing downtime and maintenance costs for industrial users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bridge Seal Expansion Joints Category

Bridge Expansion Joints

Price 35000 INR / Unit

Minimum Order Quantity : 100 Units

Type : Others, Bridge Expansion Joints

Material : Other

Surface Treatment : Galvanized

Size : As Per Requirement

Strip Seal Expansion Joint

Price 3000 INR / Unit

Minimum Order Quantity : 100 Units

Type : Others, Seal Expansion Joint

Material : Other

Surface Treatment : Galvanized

Size : As Per Requirement

Compression Seal Expansion Joint

Price 600 INR / Piece

Minimum Order Quantity : 100 Units

Type : Others, Compression Seal Expansion Joint

Material : Other

Surface Treatment : Galvanized

|

TRIDENT ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry